Testing in garment manufacturing is paramount as it determines the quality of the end product, customer satisfaction, brand reputation, and compliance with regulatory standards in the apparel industry. Apparel manufacturers face testing challenge in garment industry, from fabric inspection to post production quality control. Tackling these requires a lot of time, labor, and associated cost, which ultimately burdens the operations and makes it challenging to generate ROI. By addressing these challenges head-on, apparel manufacturers can enhance quality testing processes and deliver high-quality products. The blog discusses the importance of quality control in garment industry five common garment testing challenges and solutions to overcome the same for a high revenue-yielding garment business in a competitive market.

Importance of Quality Control in the Garment Industry

Quality control is of utmost importance in the garment industry, as it ensures the delivery of quality garments as per the set factory standards.

- Quality control ensures that garments meet standard quality expectations for enhanced customer satisfaction.

- Maintaining high-quality standards enhances brand reputation, fostering trust and competitiveness in the market.

- It ensures adherence to industry regulations and standards, avoiding legal issues and promoting sustainable manufacturing practices.

- Comprehensive quality control processes help alleviate testing challenge in garment industry by tracking defects, reducing the number of rejections in the inline and end line production.

- Effective quality control operations streamline production processes, minimize rework, optimize resource utilization, and improve overall efficiency.

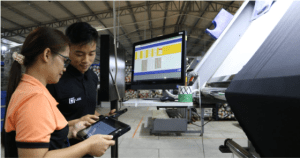

By adopting powerful quality inspection software, garment manufacturers can meet industry standards, minimize defects, and enhance production efficiency.

How to Overcome Garment Challenge in Testing

Here is a compilation of 5 common garment challenges in testing and how to overcome these using technology solutions.

Quality Inconsistency:

It refers to variations in the quality of garments produced which can lead to client dissatisfaction and harm the brand’s reputation. Garment manufacturers must establish stringent quality control processes to ensure consistent quality standards throughout production.

How to overcome:

Implement rigorous quality control processes and standardized testing protocols using a comprehensive quality management software and conduct regular quality audits.

Fabric Wastage:

Fabric wastage occurs when excessive amounts of fabric are discarded during manufacturing due to the human failure in detecting/classifying defects. This leads to increased costs and environmental impact.

How to overcome:

Train your staff on the importance of quality control in garment industry and implement efficient fabric inspection techniques using quality inspection software to eventually minimize fabric wastages and improve cost-efficiency.

Sewing Line Defects:

Unnoticed defects during the manufacturing can result in financial losses, as the garments that do not meet the quality standard are rejected.

How to overcome:

Implement comprehensive inspection checkpoints and utilize advanced defect detection technologies such as Digital Traffic Light System (TLS) to curb product inefficiencies in the production floor.

Shipment Delays Caused by Rejections:

Rejected garments at the end line can cause delays in shipment, leading to client dissatisfaction and disruptions in the supply chain.

How to overcome:

Leverage robust quality inspection software to handle pre-shipment inspections and ensure adherence to industry standards to avoid rejections and shipment delays.

Limited Scalability:

Limited scalability refers to the challenges faced while expanding production capacity and operations, such as the number of inventories, factory operations, etc.

How to overcome:

Adopt a scalable quality testing system to standardize operating procedures and establish quality control guidelines.

Conclusion

The importance of quality control in the garment industry is significant, owing to the unique characteristics of the business. Garment testing encompasses various challenges throughout the apparel production process. Automate compliance with regulatory requirements and provide customized guidelines for quality control in the preproduction, production and post-production quality inspection processes using a fabric inspection software and integrated quality management system to eliminate complexities with testing procedures in your apparel business.